PRODUCTS

Products

Oil-gas and micro-water monitoring system for transformer (photoacoustic spectroscopy)

Classification:

Key words:

The on-line monitoring technology of the dissolved gas composition in the transformer oil can detect the defects or performance deterioration of the equipment as early as possible, provide the judgment basis for the operation and maintenance of the transformer, and improve the reliability of power supply. The traditional on-line chromatographic analysis method is complicated to operate, cumbersome procedures, long monitoring cycle, and high maintenance cost in the later period, which is prone to false alarm or alarm rejection.

Photoacoustic spectroscopy as the second generation of dissolved gas in oil online monitoring technology, its measurement accuracy, higher efficiency, good repeatability and economy, the lowest limit of C2H2 exceeds the national standard of 0.5uL/L. The photoacoustic spectroscopy on-line monitoring equipment is more advanced, the daily maintenance is easier, and the comprehensive cost is lower, which represents the development trend of on-line monitoring of dissolved gas and micro water in transformer oil in the future.

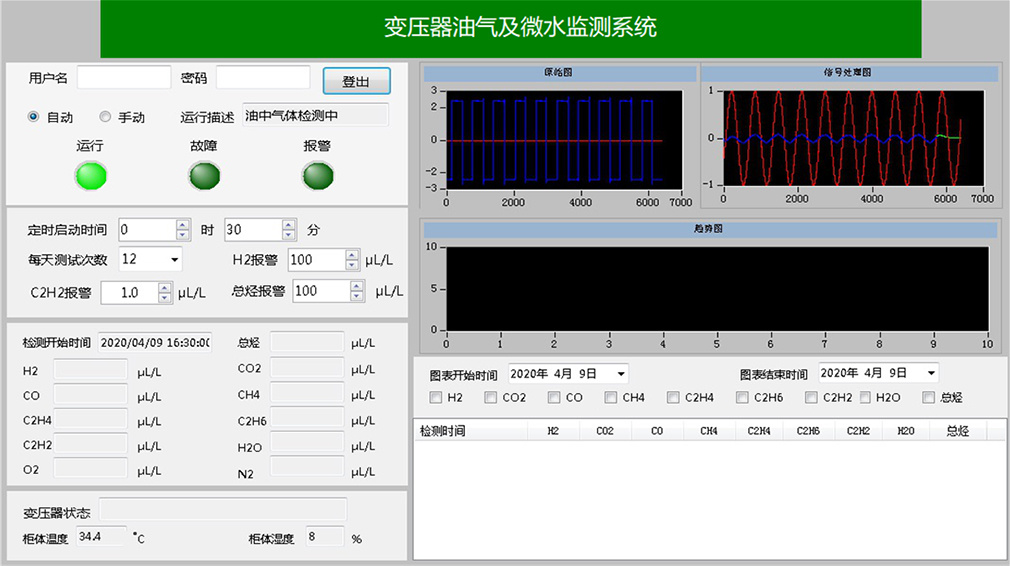

The transformer oil-gas and micro-water monitoring system consists of oil circuit system, oil-gas separation device, gas conveying device, photoacoustic spectroscopy monitoring device, system host and software background. It can carry out high-precision quantitative analysis of various gases dissolved in transformer oil and monitor the running status of large power oil-filling equipment such as transformers online in real time. The unique software expert database data diagnosis and analysis function can timely judge the monitoring equipment status and predict equipment faults.

Monitoring device

Software background

■ Main functions

1) Quantitative analysis of dissolved gases in oil: high-precision monitoring of H2, CH4, C2H6, C2H4, C2H2, CO2, CO, H2O(O2, N2 optional);

2) Historical data and trend chart: display the historical data of gas components in each time period, and can display the trend change chart of various gas components separately;

3) Fault analysis: based on David's triangle method and three ratio

value method to list the possible fault types of the transformer.

■ Main technical indicators

1) analysis cycle: minimum 50 minutes, can be set by the user;

2) Data storage life: ≧ 10 years;

3) Communication interface: provide two-way network port (can be configured as optical port),IEC61850/MODBUS/TCP(502);

4) Gas monitoring type and accuracy: as shown in the right table.

| Serial Number |

Type of gas |

Minimum detection value |

Detection range |

Detection accuracy |

| 1 |

H2 |

2 |

2~2000 |

± 2 or ± 30% |

| 2 |

CH4 |

0.5 |

0.5~1000 |

± 0.5 or ± 30% |

| 3 |

C2H6 |

0.5 |

0.5~1000 |

± 0.5 or ± 30% |

| 4 |

C2H4 |

0.3 |

0.3~1000 |

± 0.5 or ± 30% |

| 5 |

C2H2 |

0.2 |

0.2~1000 |

± 0.5 or ± 30% |

| 6 |

CO2 |

25 |

25~15000 |

± 25 or ± 30% |

| 7 |

CO |

5 |

5~5000 |

± 5 or ± 30% |

| 8 |

H2O |

1 |

1~100 |

± 1 or ± 30% |

| 9 |

O2-Optional |

100 |

100~50000 |

± 100 or ± 30% |

| 10 |

N2-Optional |

1% |

1%~100% |

±30% |

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.