PRODUCTS

Products

Intelligent Management System of Transformer Dynamic Load

Classification:

Key words:

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The system is composed of transformer load intelligent management device, indoor cabinet, outdoor cabinet and data management platform. It can monitor transformer operating conditions in real time, provide information such as oil average temperature, winding average temperature, winding hot spot temperature, etc., and realize high temperature warning, transformer load capacity evaluation and transformer cooling fan intelligent switching operation. Based on the transformer parameters and operating conditions, the system evaluates the transformer safe operation load and safe operation time in real time, realizes the fine and intelligent management of transformer operation load and life, and provides scientific and credible technical support for effectively solving the problem of limited transformer transmission capacity under N-1 operation mode.

Transformer load intelligent management device (indoor)

Outdoor cabinet

data management platform

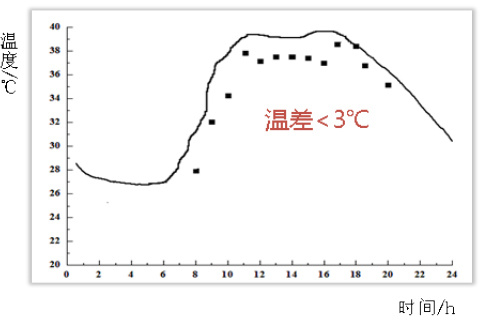

Comparison between the hot spot temperature value calculated by the model and the measured value of the optical fiber

Transformer overload capacity warning curve

■ Main functions

1) Monitoring and early warning of working conditions and temperature field information: real-time monitoring of transformer operating load, substation sunshine intensity, ambient temperature, wind speed, etc.; real-time calculation of transformer internal top oil temperature rise, oil average temperature rise, line oil temperature difference, winding average temperature rise, winding hot spot temperature rise, and early warning according to the corresponding information.

2) On-load capacity assessment and safety risk control: considering the multiple influencing factors of the on-load capacity of the transformer, integrating the real-time electrical and environmental parameters of the transformer, taking the current operating condition as the initial condition, dynamically analyzing the safety-load capacity of the transformer in the long-term or set safe operating time, and the safe operating time under different overload multiples, realize the visual display of the load capacity and safe operation time of the transformer (draw the overload capacity curve);

3) fan adaptive switching (optional): according to the operation of the transformer to achieve intelligent cooling fan switching control, energy saving and efficiency;

4) Thermal life loss assessment: according to the real-time load, operating temperature and other information, real-time assessment of transformer life loss, to ensure that the transformer in the safe and reliable operation of the premise to maximize its service life;

5) Transformer insulation life monitoring and early warning (optional): Based on the analysis conclusion data of dissolved gas in oil and the characteristic value extraction algorithm, the transformer insulation aging state is judged, and the potential insulation risk of the transformer is warned in time.

■ Main technical indicators

1) The system can increase the annual average load capacity of the transformer by 15% ~ 30%, and the load capacity under extreme weather by 5% ~ 15%;

2) The system supports multiple communication protocols: 61850, 101, 104 protocols or custom methods;

3) Applicable to oil-immersed transformers with voltage level of 110kV and above;

4) Support a variety of transformer cooling methods: ONAN, ONAF, ODAF, etc;

5) products meet IEC-61000 standards.

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.