PRODUCTS

Products

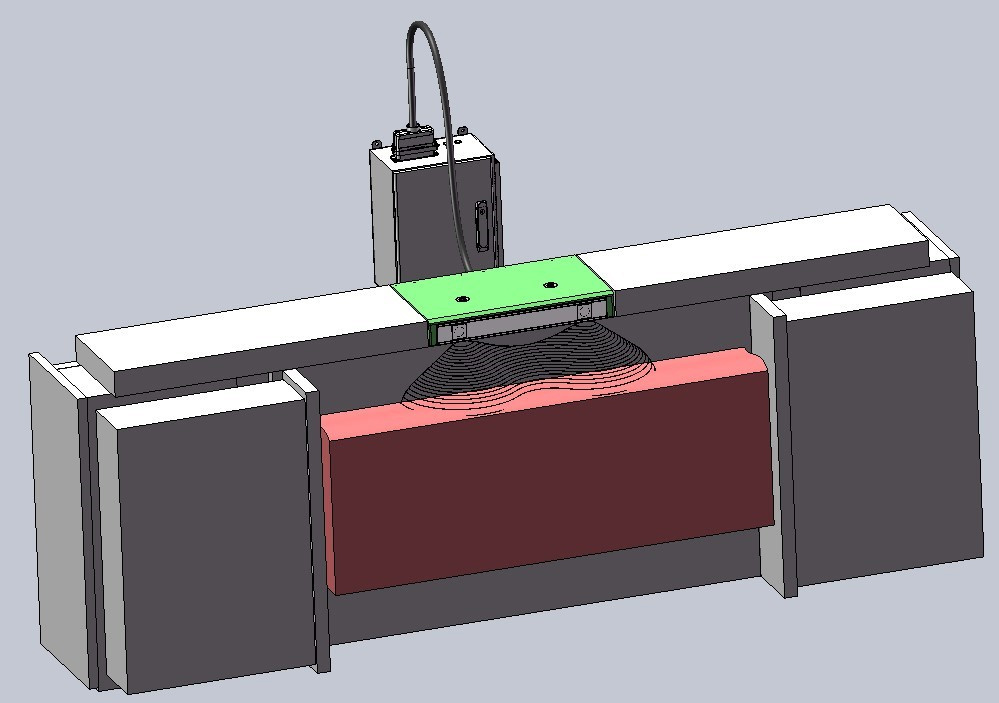

Embedded liquid level detection system

Classification:

Key words:

System Introduction

The embedded molten steel level detection system uses the principle of electromagnetic induction to detect the height of the molten steel level, and detects it through a differential circuit composed of two sensors, and its level signal can meet the requirements of automatic pouring.

Technical performance and system indicators

| Measurement accuracy: ≤ 1mm soil |

Response time: 0.1s ~ 2 5S |

| Control accuracy: ≤ soil 2mm |

Measuring range: 0~180mm |

Detecting the liquid level of molten steel in the crystallizer, eliminating the influence of protective slag and casting material on the liquid level on the surface of molten steel, and adapting to the continuous casting process of multiple steel grades. The sensor is made of stainless steel as a whole, cooled by cooling water, and has a longer service life.

Previous Page

Next Page

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.