PRODUCTS

Products

Precise fault location and early warning device for high-voltage cable (hybrid) lines

Classification:

Key words:

The operating environment of power cables includes a variety of complex occasions, including direct burial, pipe penetration and cable trenches, which are particularly difficult for operation and maintenance personnel to access. Once a power cable breakdown occurs at these locations, the point of failure cannot be quickly identified.

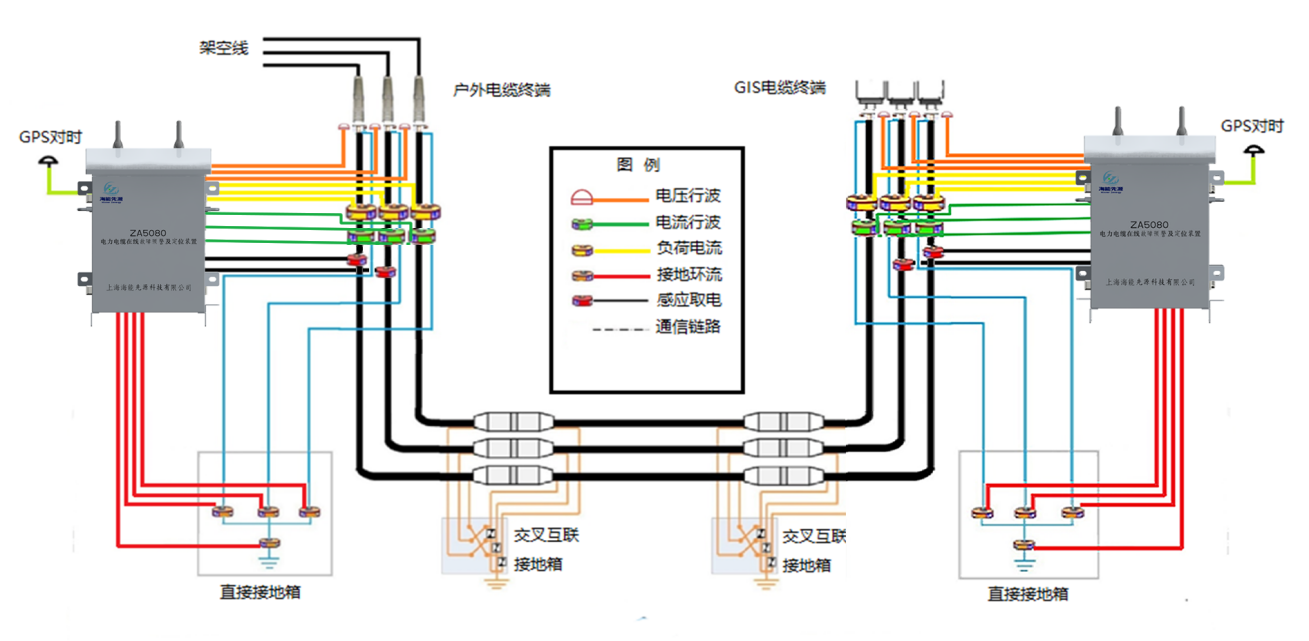

The high-voltage cable (hybrid) line fault precise location and early warning device monitors the cable waveform in real time, and collects the high-frequency traveling wave signal excited when the cable fault occurs through high-frequency sensors installed at both ends of the cable. Through high-speed sampling and wavelet transformation, high-precision GPS and Beidou timing are added to completely present the timing and morphological information of the fault waveform. Artificial intelligence algorithm is used in the background to achieve the purpose of fast recording and accurate automatic location of the fault.

Product features:

The product has the combined fault detection of non-contact voltage traveling wave sensor and current traveling wave sensor, supports double-ended positioning and single-ended fast positioning mode, and the positioning accuracy is ≤ 0.1 L +5m; Optimized combination of voltage and current sensors completes the acquisition of various transient waves in the cable system; GPS and Beidou accurate timing systems ensure timing accuracy ≤ 20ns; Based on a large amount of cable wave data, the AI deep learning algorithm is used to provide accurate positioning, the fingerprint database of various working conditions of the cable is used, and the AI algorithm is combined to improve the accuracy of fault warning, and the AC220V, solar energy, induction power supply and other schemes are adapted to various working conditions.

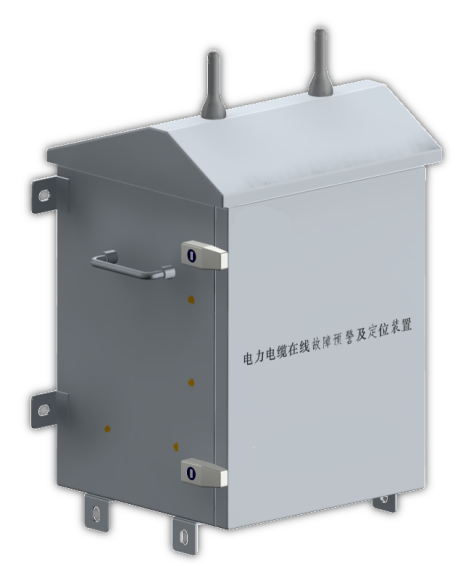

| Technical indicators: Detection head rising edge: ≤ 100ns Sampling frequency: ≥ 20MHz Working temperature:-40~50 ℃ Protection grade: box IP67, sensor IP68 Communication mode: 4G Sensor: non-contact; can be installed with electricity Local storage: ≥ 100 fault records, no loss after power failure Shell material: SUS304 stainless steel |

|

Next Page

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.