PRODUCTS

Products

Intelligent Early Warning System for Operation State of Transmission Line Key Clamp

Classification:

Key words:

Affected by natural and man-made factors, the contact resistance of some key wire clamps (strain clamp, wire connection tube, etc.) of transmission lines is too large, and there is a risk of overheating when encountering heavy load, and its temperature may exceed the safety limit. At this time, the wire clamp not only has the risk of burning loss, but also its mechanical strength will decrease, which seriously affects the safety of line operation.

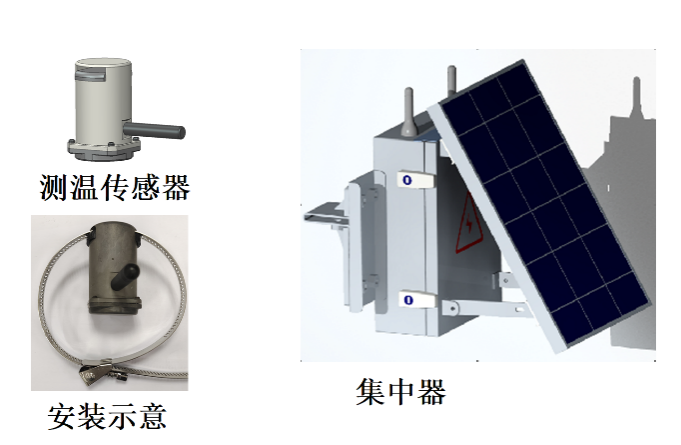

The intelligent early warning system for the operation state of key line clamps of transmission lines is composed of temperature measuring sensors, concentrators and software background. By installing temperature measurement sensors at each key line clamp, installing concentrators nearby, and transmitting data to the software background through APN private network, temperature monitoring, temperature rise warning and defect location at key points such as transmission line clamps can be realized.

Through the early warning and fault trend prediction of the hidden dangers of transmission line clamps, we can take targeted measures in the early stage of accident development, timely maintenance, and prevent the accident from expanding, which is of great significance to the safe operation of the power grid.

Main functions

• Condition monitoring

The temperature of each key wire clamp is obtained in real time, and the historical temperature curve and temperature rise prediction curve are drawn.

• Defect warning

Based on the big data analysis algorithm, the intelligent identification of hot fault points and fault classification early warning are realized.

• Fault trend prediction

The temperature rise prediction curve is drawn for the defect point of serious thermal fault, and the safe operation time is evaluated.

• Load monitoring (optional)

Real-time monitoring of line running current.

Main technical indicators

1) Applicable to 110kV ~ 500kV voltage level transmission lines (towers);

2) The temperature measuring sensor has high communication stability, easy installation, maintenance-free, and service life ≥ 5 years;

3) A single concentrator supports up to 24 measuring points;

4) Wide working temperature range (-40 ℃ ~ 120 ℃), high protection level, can adapt to outdoor harsh weather conditions;

5) Temperature measurement range and accuracy:-50 ℃ ~ 150 ℃,± 2 ℃.

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.