PRODUCTS

Products

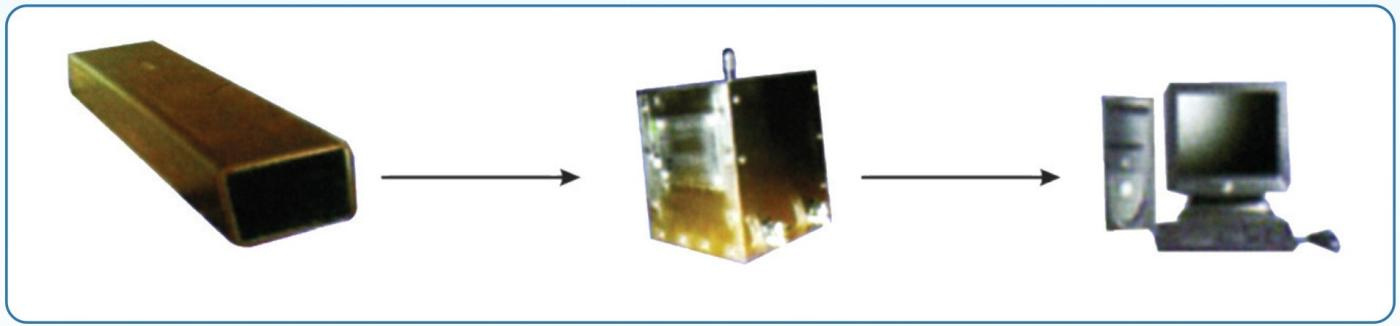

Portable crystallizer taper meter

Classification:

Key words:

Taper meter is a special detection equipment for continuous casting production, it is based on micro single-chip microcomputer as a computing tool, imported special space sensor as the main sensing element, it can quickly and accurately read the continuous casting machine mold narrow face copper plate of the actual taper number. The instrument has the characteristics of perfect function, easy to use, accurate measurement data and good repeatability, and is suitable for crystallizers of various lengths. The instrument can ensure the accuracy of the mold taper measurement, ensure good heat transfer and cooling effect of the billet shell and the mold, prevent the narrow surface from leaking steel, and improve the narrow surface support.

Taper meter is a special detection equipment for continuous casting production, it is based on micro single-chip microcomputer as a computing tool, imported special space sensor as the main sensing element, it can quickly and accurately read the continuous casting machine mold narrow face copper plate of the actual taper number. The instrument has the characteristics of perfect function, easy to use, accurate measurement data and good repeatability, and is suitable for crystallizers of various lengths. The instrument can ensure the accuracy of the mold taper measurement, ensure good heat transfer and cooling effect of the billet shell and the mold, prevent the narrow surface from leaking steel, and improve the narrow surface support.

Technical performance and system indicators

▶Accurate data, high precision, good stability, good repeatability, suitable for harsh environment;

▶Sensor with special protection circuit to prevent electrostatic damage, long-term stable work;

▶Self-supporting, self-centering, easy to operate;

▶Keep constant pressure on the narrow surface for easy counting;

▶Indication lock function, double-row digital display;

▶Dedicated battery power supply, and with protection function, longer life, longer single use time;

▶Suitable for straight plate, arc, parabolic, diamond crystal copper tube.

Next Page

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.