PRODUCTS

Products

Temperature Monitoring and Early Warning System for Key Points of Electrical Equipment

Classification:

Key words:

System function

Temperature sensors are arranged in key parts of electrical equipment that are easy to heat up, and the temperature and temperature rise changes of each point are monitored in real time. According to the judgment principle of different monitoring points with the same phase and different phases of the same monitoring point, the temperature and temperature rise changes of each monitoring point are evaluated hierarchically, hidden dangers of electrothermal accidents are found in time, and hidden faults are prevented from becoming manifest or even becoming accidents.

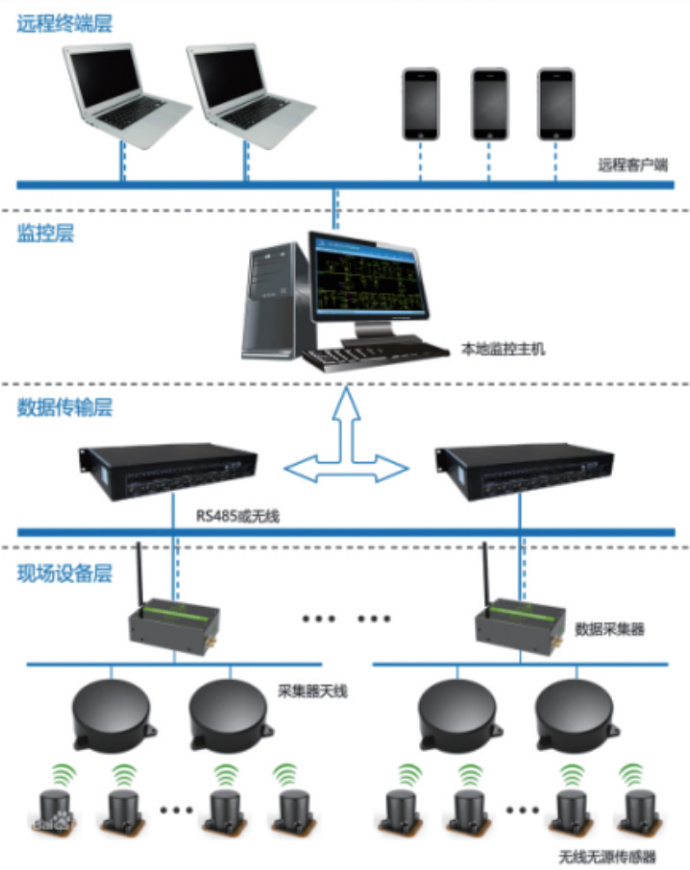

The system consists of a wireless passive temperature sensor, a data collector and a background management system (mobile phone APP can also be used) to visually display the monitoring information, evaluation information and early warning information of each monitoring point and monitored equipment.

Application Scenarios

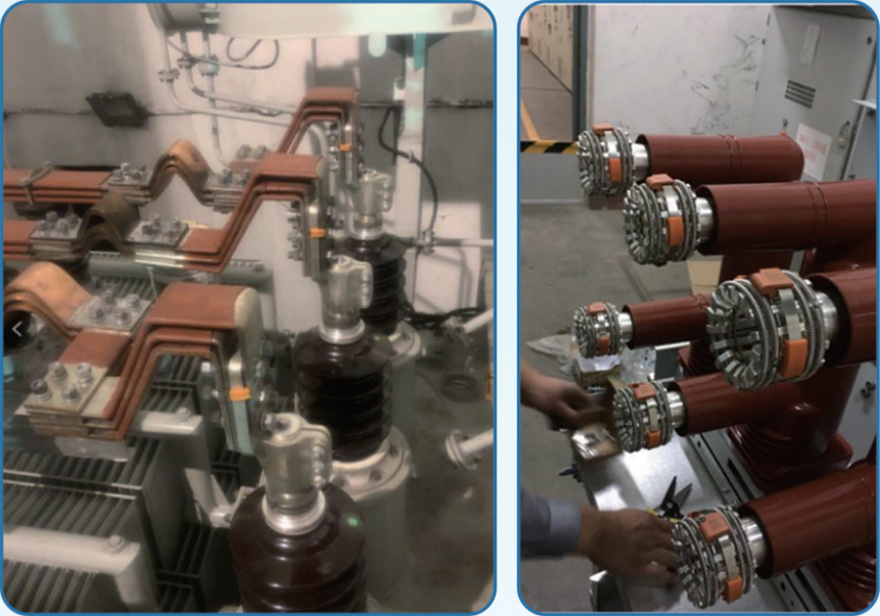

▶Equipment clamps for through-flow electrical equipment;

▶Terminal head at each side of transformer;

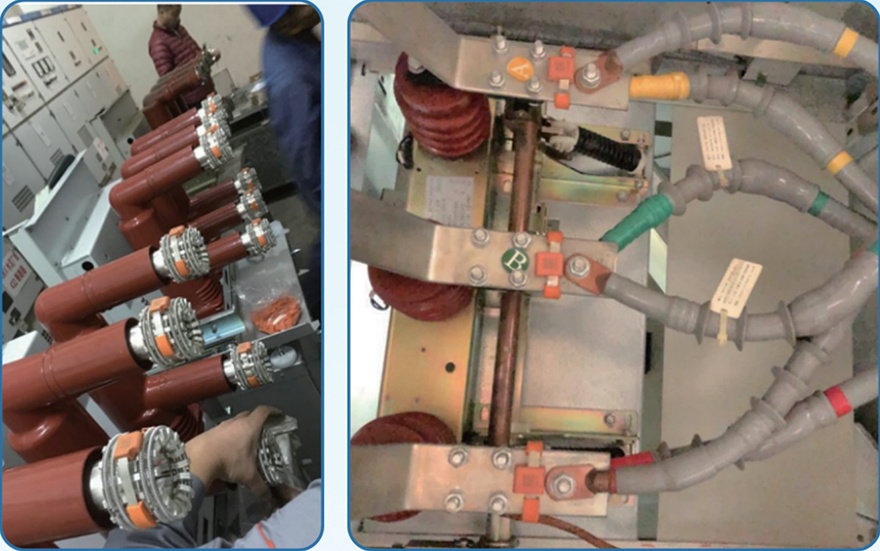

▶Power distribution room busbar and wall bushing;

▶Switch cabinet breaker contact and knife switch moving contact;

▶Feeder and its branch connection points;

▶Cable joints and intermediate joints.

Temperature sensor

Technical performance and system indicators:

| Temperature measurement range:-40~125 ℃ |

Measurement accuracy: ± 0.5 ℃ |

| Temperature sampling frequency: 1~10s |

Wireless frequency: 433, 470MHz |

| Wireless transmission distance: ≤ 300 m (open distance) |

Working power: induction power |

| Installation method: binding type (non-invasive installation) |

Working current: ≥ 5A |

| Temperature sensing body size: 26mm * 22.5mm * 10mm |

|

Data Collector

Technical performance and system indicators:

| Wireless Frequency: 2.4GHz/433MHz |

Number of wireless sensors: ≤ 240 |

| Wired communication: RS485, Ethernet, optical fiber |

Access quantity: ≤ 128 sets |

| Communication Protocol: Modbus |

|

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.