PRODUCTS

Products

Automatic billet feeding control system

Classification:

Key words:

System Introduction

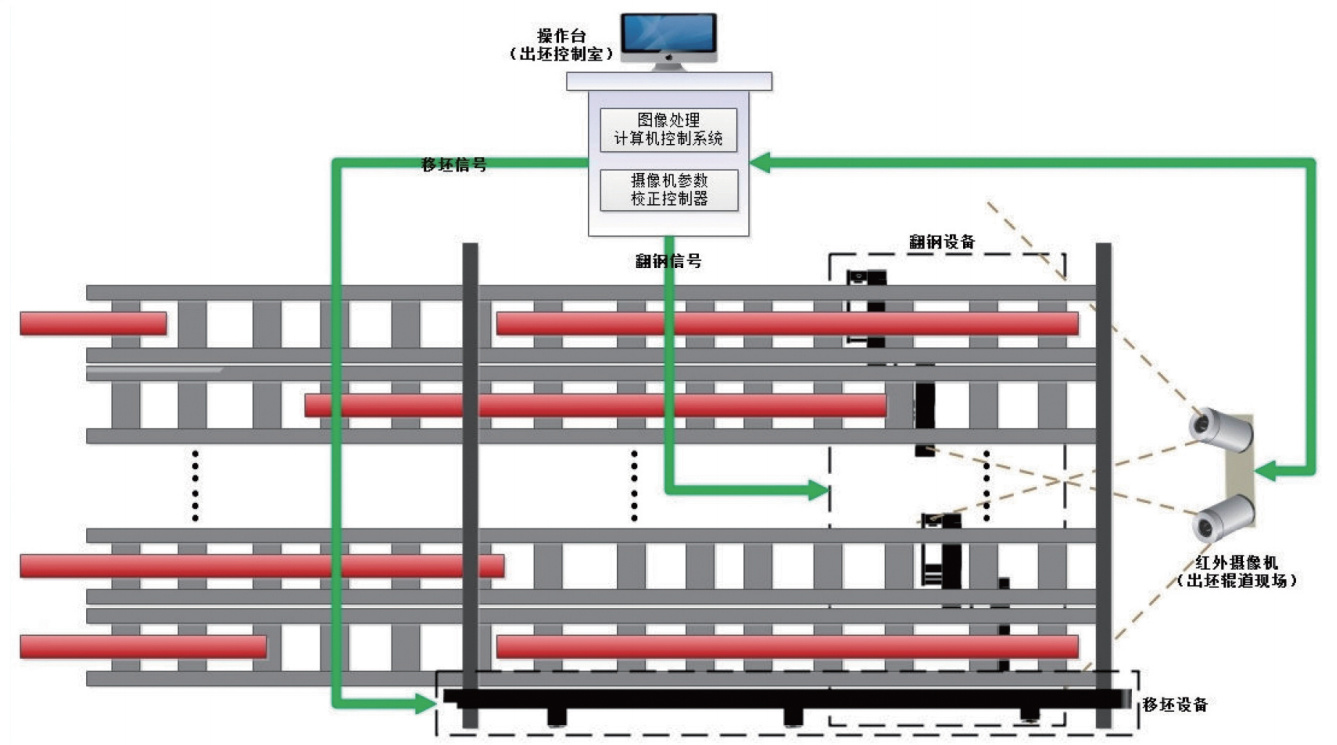

The system collects the images of the cast billet remotely through infrared camera technology, and uses advanced image recognition technology to identify the position of the cast billet in real time. After the cast billet is in place, the system automatically sends the steel turning signal to control the steel turning equipment to turn the cast billet, and according to the set billet moving strategy, the system automatically sends the billet moving signal to control the billet moving equipment to move the billet, with high degree of automation, which can effectively improve work efficiency and reduce labor cost.

System working principle

System Indicators

● System response time: 0.1s;

● Signal transmission without distortion distance: 100m;

● Correct identification rate of cast billet in place:>98%.

System features

Infrared non-contact detection, easy maintenance;

● The identification rate of cast billet in place is high, and the strategy of turning steel and moving billet can be dynamically adjusted to facilitate production;

● High degree of automation, and automatic and manual mode free switching;

Friendly operation interface, dynamic adjustable control parameters, visual display of production.

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.