PRODUCTS

Products

Continuous casting machine mold liquid level automatic pouring system

Classification:

Key words:

One-key automatic pouring system for molten steel level in mold: a new benchmark for intelligent manufacturing in the foundry industry

With the wave of intelligent manufacturing, the degree of automation in the steel industry is rapidly improving. Whether the continuous caster has the ability of "one-key automatic pouring" has become an important symbol to measure its automation level and production process. Although some domestic iron and steel manufacturing enterprises have begun to explore the one-click automatic pouring technology of tundish for billet continuous casters, the cases of achieving stable operation are still limited, and most production scenarios still rely on a large number of manual operations.

As one of the few enterprises in China that has mastered the complete set of plug rod automatic control system and one-key pouring technology, Haineng Technology has launched the "one-key automatic pouring system for molten steel level of crystallizer" relying on profound technology accumulation. This product is specially designed to improve the stability, efficiency and safety of steel production, and provides customers with refined, integrated and high-quality automation solutions for steel manufacturing enterprises.

● Innovation and breakthrough: one-key automatic pouring system, leading the new trend of the industry

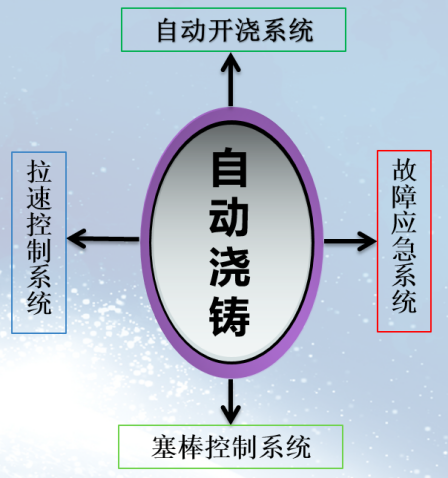

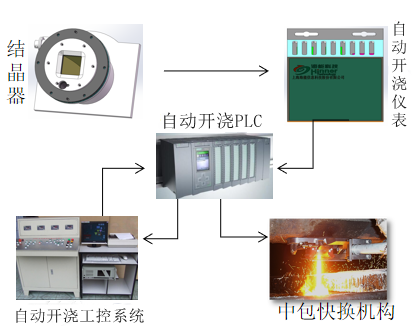

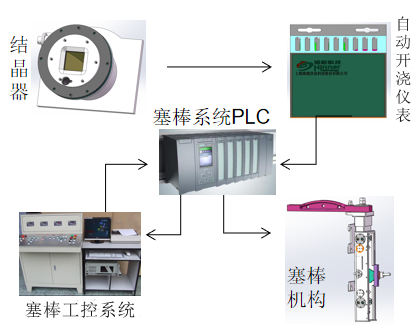

The traditional pouring process often relies on manual operation, which has problems such as cumbersome operation and low efficiency. As the core innovative product of Haineng, the "One-key Automatic Pouring System for Molten Steel Level in the Mold" integrates automatic control technology and precise calculation, realizes the seamless switching of molten steel after entering the mold, and quickly switches from the pouring mode to the automatic steel pulling mode to achieve direct automatic liquid level control. At the same time, combined with the frequency conversion adjustment technology, through high-power servo control, high-frequency and high-speed oscillation adjustment can be realized, which can meet the automatic pouring needs of a variety of processes.

Each step of automatic pouring is precisely controlled, and an independent early warning control unit is used to ensure the stability of the mold level and the efficient pouring of molten steel, so as to greatly reduce the accident rate of steel leakage and steel overflow and improve the qualification rate of the billet. In addition, advanced algorithms and auxiliary means also make the pouring time accurate and controllable, which is truly in line with the industry vision of "intelligent manufacturing".

● Product Highlights: Highly adaptable system solutions to meet diversified production needs

According to different steel production needs, Haineng Technology has designed two automatic pouring systems, "pull speed type" and "plug rod type", to provide efficient and stable customized support for complex production environments and changeable casting needs:

· Pulling speed automatic pouring system: the pulling speed liquid level control of the continuous caster realizes the precise change of molten steel level by optimizing the liquid level adjustment mode and supplemented by the control of the blind plate mechanism. The pulling speed system effectively replaces manual operation, realizes the smooth transition of "one-key automatic pouring", and ensures the safety and efficiency of the pouring process.

· Plug rod type automatic pouring system: deeply integrate the core function of plug rod control, and realize the accurate pouring of molten steel in the mold through intelligent detection and control. Through the collaborative control between the plug rod equipment, the tension leveling system and a variety of signals, the system ensures the high stability and high efficiency of the pouring process, especially suitable for production scenarios that require flexible adjustment, and greatly improves the adaptability of the system.

● Comprehensive benefits: Intelligent manufacturing empowers the high-quality development of steel manufacturing

The "one-key automatic pouring system for mold molten steel level" not only brings customers an excellent automation experience, but also achieves cost reduction, efficiency increase and safety improvement through precise control:

· Significant cost optimization: Taking the casting scenario of 8-stream 150 billets as an example, about 200 pouring operations are carried out every year, and the automatic pouring liquid level range is 30-180 mm, which can reduce the amount of head billet cutting waste by 1.2 meters per pouring and reduce about 341 tons of scrap steel throughout the year, which significantly saves material consumption and directly optimizes the production cost of the enterprise.

· Efficient operation process: The traditional manual pouring needs to be repeatedly deployed between different processes, while the response time of the automatic pouring system is less than 100 milliseconds, so that each operation can save 40-50 seconds of operation time. For enterprises with high production needs, this efficiency improvement will also lead to more competitive production levels.

· Significantly less labor-intensive: In the intelligent mode of automatic pouring operation, a single stream operation can be carried out by only 1 operator. Compared with the traditional two-person operation mode, if the individual salary is 5,000 yuan/month and the three-shift rest system is calculated, the labor cost can be reduced by 720,000 yuan per year. The reduced manpower consumption not only makes the operation process more efficient, but also makes the allocation of human resources more flexible.

· Higher safety factor: The system design controls the accident warning response time below 100 milliseconds through multi-level precision calculation and fault chaining, and reduces the pouring accident rate by more than 99%, which provides a reliable guarantee for the production process of the enterprise, reduces the risk of accident shutdown, and ensures the continuity and safety of the production process.

● Market application: strong evidence of customer success stories

Since its launch, the "one-key automatic pouring system for mold molten steel level" has been widely used in many domestic iron and steel enterprises, and customer feedback has been widely positive. Here's how the system is being used in some of our customers:

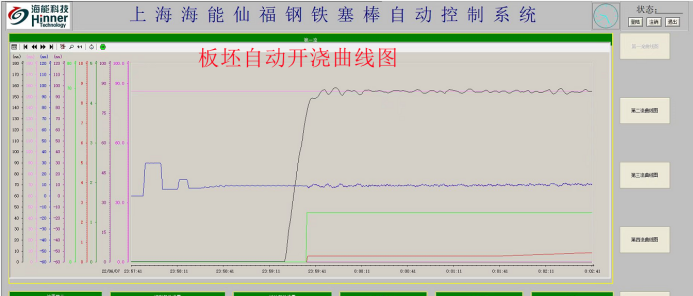

· Jianlong Agang Steelmaking Plant: The continuous casting operation area of Jianlong Agang Steelmaking Plant actively promotes intelligent manufacturing, and in 2021, the automatic pouring system of flat billet plug rod was launched, which was successfully put into use at one time. With the joint efforts of all the project team, the system was debugged in only 12 days, which significantly reduced the labor intensity of employees and effectively guaranteed the stable operation of the continuous caster.

· Nanjing Iron & Steel Electric Furnace Plant: Based on the original plug rod automatic control system, the plant has been successfully upgraded to automatic pouring + plug rod control system, which is suitable for 150*150, 165*220 and other cross-sectional specifications, and has achieved excellent production results.

· Qingdao Iron & Steel: The billet continuous caster of the enterprise has adopted the marine energy system since it was put into operation, and the success rate and stability of pouring are in the leading position in the country.

(The picture shows Qingdao Iron and Steel's 8-flow casting machine, after using automatic pouring, only 2 people are on duty.) )

· Yunnan Xianfu Iron & Steel: The automatic pouring system of the slab of machine 5 realizes the automatic pouring of fully automatic, semi-automatic and sizing nozzles, which is suitable for 180*700 and 180*800 section specifications.

· Fujian Sangang Minguang Iron and Steel, Changshu Longteng Special Steel Co., Ltd., Fushun New Iron and Steel, etc., have also realized the innovative application of the country's first short-range automatic pouring system.

● Future outlook of intelligent manufacturing: create new value with the steel industry

Haineng Technology's continuous breakthroughs in the field of intelligent manufacturing have consolidated its leading position in the automation and efficient integration of steel production. And adhere to innovation-driven, continue to optimize product performance, and explore smarter and more efficient production solutions. We look forward to working with the steel industry to move towards a new era of intelligent manufacturing, jointly create tangible value for steel manufacturing enterprise customers, and lead the high-quality development of the steel industry with technology and quality!

Previous Page

Next Page

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.