PRODUCTS

Products

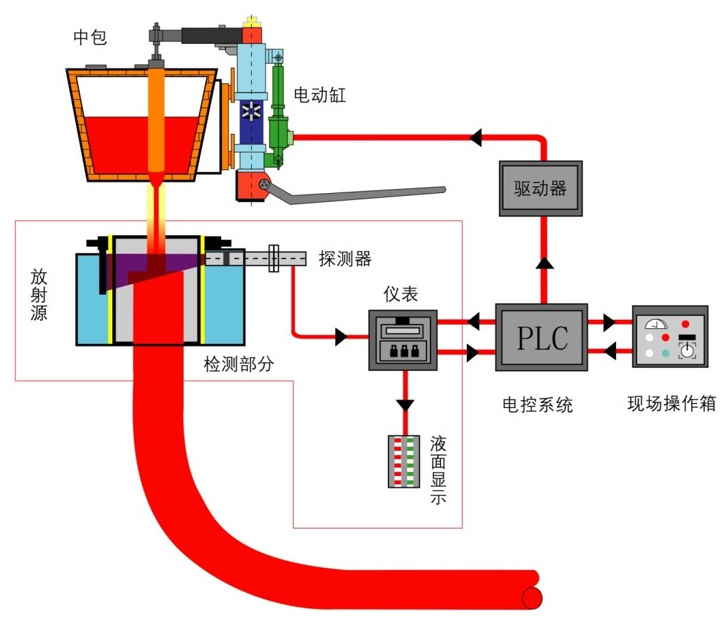

Automatic control system for tundish stopper

Classification:

Key words:

System Introduction

The system adopts stable molten steel level detection system, advanced digital electric cylinder and plug rod actuator and other equipment to accurately control the molten steel flow of the tundish, so that the molten steel level in the continuous casting mold is stable, and the automatic control effect of constant liquid level and constant pulling speed is achieved.

Technical performance and system indicators

| Detection range: 0~180mm (adjustable) |

Convergence time: 100ms |

| Electric cylinder weight: 15kg |

Liquid level control accuracy: ≤ ± 3mm |

| Temperature resistance of electric cylinder:-20 ℃ ~ 95 ℃ |

Stroke control accuracy: 0.01mm |

| Actuators thrust: 500kg (adjustable) |

Working temperature of electrical system: ≤ 70 ℃ |

| Response time: 100ms |

Working humidity of electrical system: ≤ 90% without condensation |

System features

● The plug rod actuator equipment is easy to operate and has high precision;

● Imported high temperature servo motor, imported screw, good acceleration performance, constant torque output, smooth operation;

● The plug rod micro-motion function makes the flow of molten steel more stable;

● Self-cleaning function effectively prevents the blockage of the water outlet in the package;

The nozzle protection function can extend the service life of the nozzle;

● Manual/automatic switching, automatic pouring function;

● High and low alarm and delay closing stopper to avoid steel overflow or steel leakage.

Your suggestion is our driving force

Related Products

The transformer dynamic load intelligent management system is used to solve the problems of low operating efficiency of large transformers, difficulty in internal temperature monitoring, and limited operation of transformers under heavy (over) load, and to improve the operating efficiency of transformers without affecting the service life and safe operation of transformers.

The dynamic load management system of transmission line is used to solve the problems such as limited load capacity of transmission line and difficult to meet the demand of load growth, and to improve the operation level and load capacity of the line without changing the existing network structure and without affecting the thermal stability of the line.

Due to the technical limitations of the traditional transmission line fault location device, it is difficult to quickly and accurately locate the fault point and identify the fault type when the fault of the transmission line occurs in the complex operating environment (lightning strike, mountain fire, wind deviation, tree barrier, floating object, etc.). The distributed fault diagnosis device for transmission lines is based on fault local recording technology and traveling wave location method, which can effectively solve the problems of low positioning accuracy and difficult identification of fault types of traditional fault location devices.